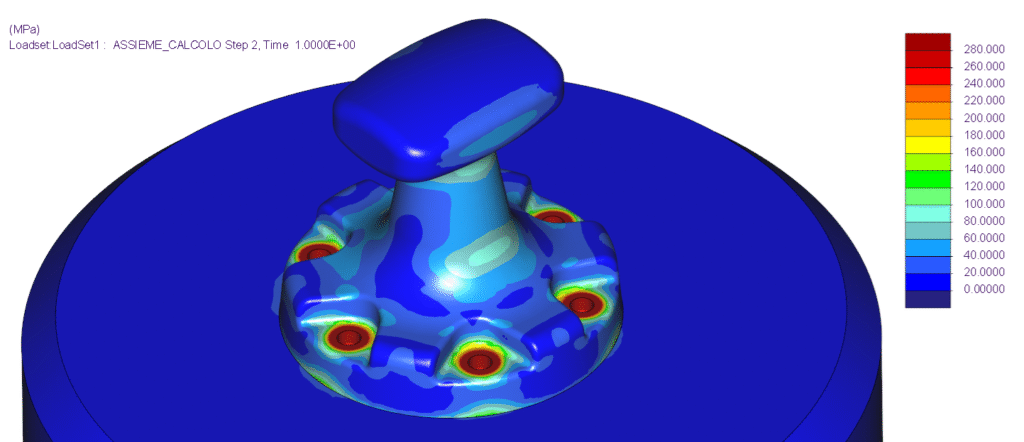

Advanced FEM analysis of a Port Bollard in Creo Simulate

Ensuring Structural Integrity Through Accurate Contact and Bolt Preload Simulation

Introduction

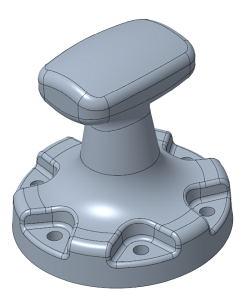

Port bollards are critical safety components in any marina or commercial port, designed to withstand immense mooring forces from vessels. A simple linear static analysis is often insufficient to guarantee their real-world performance and safety. To ensure the utmost reliability of our designs, Altamax Engineering employs advanced Finite Element Method (FEM) analysis that accurately simulates the complex interactions at play.

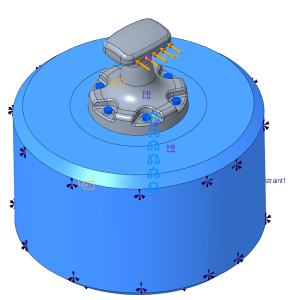

This case study details our structural analysis of a cast steel port bollard, focusing on two critical aspects: the non-linear contact between the bollard base and the concrete quay, and the crucial effect of bolt preload. The analysis was performed using PTC Creo Simulate.

The Challenge: Simulating Real-World Conditions

The structural integrity of a mounted bollard does not depend solely on the strength of the bollard casting itself. It relies heavily on the clamping force exerted by its mounting bolts and how that force is distributed onto the quay.

- Contact Interaction: The interface between the bollard’s steel base and the concrete quay is a compression-only relationship. The components cannot penetrate each other, and under extreme operational loads, parts of the base may tend to lift or “gap” if the bolt preload is insufficient. This behaviour is non-linear and must be accurately modeled.

- Bolt Preload: The high-tensile bolts are tightened to a specific torque, inducing a significant tensile pre-stress (preload). This preload creates a powerful clamping force that holds the bollard firmly against the quay, ensuring that frictional forces can contribute to resisting shear loads and preventing gapping under tensile loads. Failing to model this preload would lead to a completely inaccurate understanding of the stress state in both the bolts and the bollard assembly.

Methodology in Creo Simulate: A Two-Step Approach to Preload

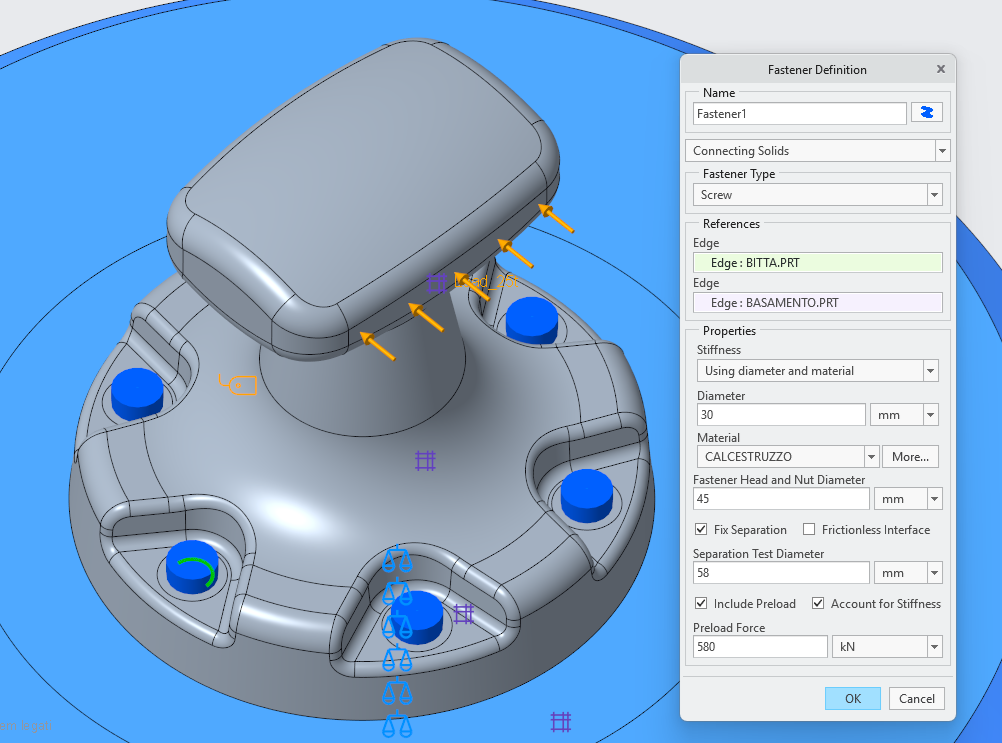

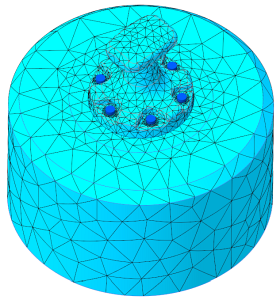

Creo Simulate provides a powerful and precise, albeit indirect, method for simulating bolt preload using a thermal contraction technique. Our analysis was conducted in two main stages, leveraging the P-type mesh refinement capabilities of Creo Simulate to ensure highly accurate results with computational efficiency.

Step 1: Preliminary “Calibration” Analysis

The first step is to determine the correct thermal load that corresponds to the required preload force for a single bolt.

- Objective: To find the specific thermal load value that, when applied to a bolt with a defined coefficient of thermal expansion (α), results in the precise target preload tension (e.g., 75% of the bolt’s proof load as per industry standards).

- Procedure: A simplified model containing only a single bolt and small representative sections of the clamped parts is created. We assign a known coefficient of thermal expansion to the bolt material. A thermal load is then applied to the bolt, causing it to contract and generate a tensile force.

- Calibration: By measuring the resulting axial force in the bolt, we iteratively adjust the magnitude of this thermal load until the measured force perfectly matches our target preload force (e.g., 500 kN). This calibrated thermal value now becomes a reliable equivalent for the mechanical preload.

Step 2: Definitive Full-Assembly Analysis

With the calibrated thermal load established, we proceed to the analysis of the complete assembly.

- Model Setup: The full model, including the bollard, all mounting bolts, and a section of the concrete quay, is assembled. A “Contact” interface is defined between the bollard’s base and the quay surface, allowing them to separate but not to penetrate each other.

- Load Application:

- Preload: The calibrated thermal load from Step 1 is applied to all bolts in the assembly. This simulates the uniform tightening of the bolts and accurately establishes the initial clamping force and stress state before any operational loads are considered.

- Operational Load: The maximum design mooring line pull is applied to the bollard head at the specified critical angle.

- Simulation Run: A non-linear static analysis is executed, solving for stresses, displacements, and contact pressures throughout the assembly.

Results and Benefits

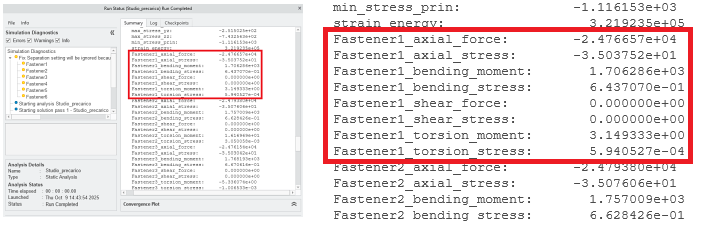

This detailed simulation methodology provided invaluable insights that a simplified analysis would have missed:

- Accurate Stress Distribution: The analysis revealed the true stress state in the bolts, showing the combination of the initial preload and the additional stress from the operational load. This confirmed that the bolts would not exceed their allowable stress limits.

- Contact Pressure Verification: We were able to visualize the pressure distribution on the concrete quay, ensuring it was within the material’s compressive strength limits and identifying any high-pressure points.

- Gapping Prevention: The simulation confirmed that the calculated preload was sufficient to prevent any part of the bollard base from lifting off the quay under the maximum design load, ensuring a stable and rigid connection.

- Design Optimization: By understanding the precise load paths and stress concentrations, we could confidently optimize the bollard’s design for material efficiency without compromising on its strength or safety factor.

Conclusion

By employing a meticulous two-step preload simulation and accurate contact modeling in Creo Simulate, Altamax Engineering validates its designs against real-world physics. This advanced approach moves beyond simplified assumptions to deliver bollard designs that are proven to be safe, durable, and fully compliant with the highest industry standards, providing our clients with unparalleled confidence and reliability.