Nonlinear FEM Simulation of a Cardan Joint – Contact and Plasticity Analysis

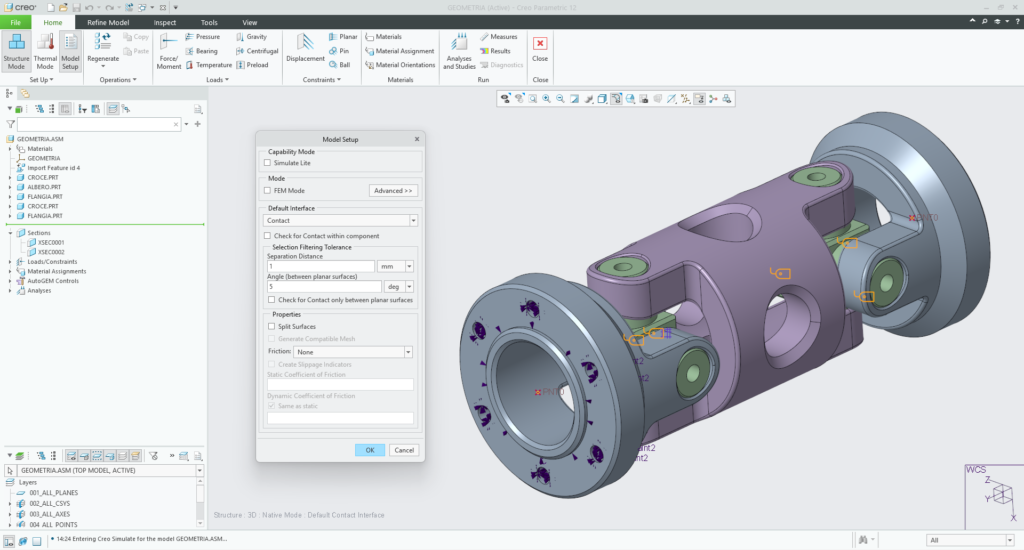

The simulation was performed using Creo Simulate Advanced 12.0.

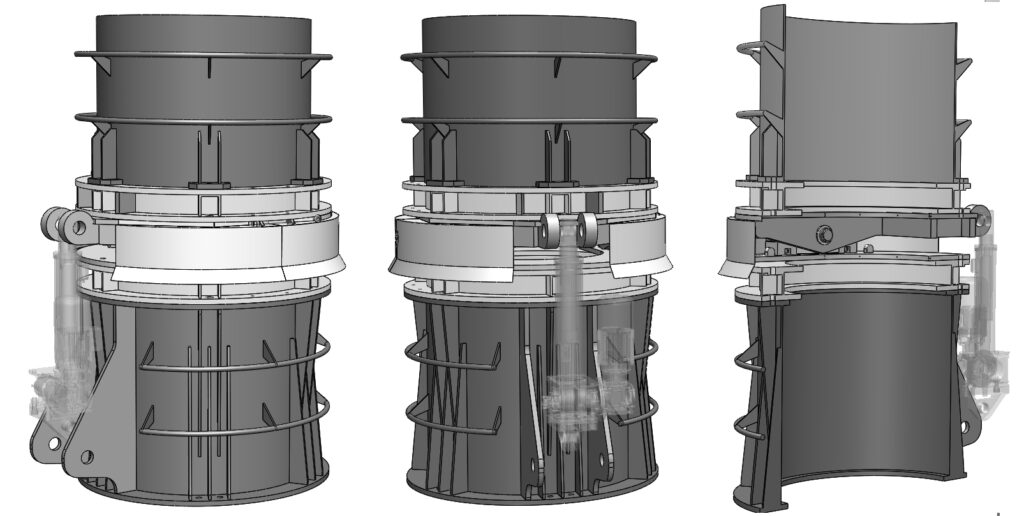

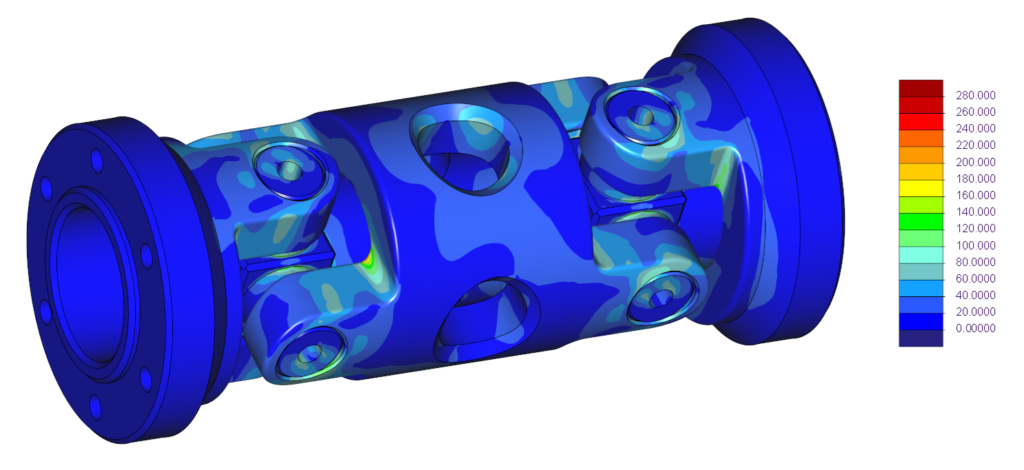

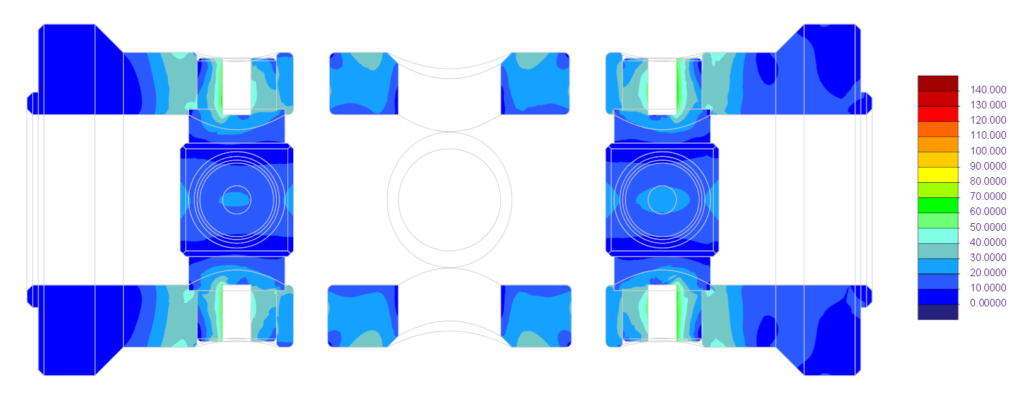

The analyzed model represents a double Cardan joint, featuring eight cylindrical contact interfaces and an equal number of planar contact surfaces, which constrain and suppress the sliding degree of freedom along the pins. As a result, the problem exhibits a pronounced nonlinear behavior. This case study illustrates our capability to perform advanced nonlinear FEM simulations for industrial assemblies, including contact, friction and material plasticity, as part of our engineering consulting and outsourcing services. Mechanical assemblies with multiple contact interfaces, such as cardan joints, pose significant challenges for standard linear analysis approaches. Accurate prediction of stress distribution, permanent deformations and contact pressures requires nonlinear FEM simulations accounting for contact, friction and material plasticity.

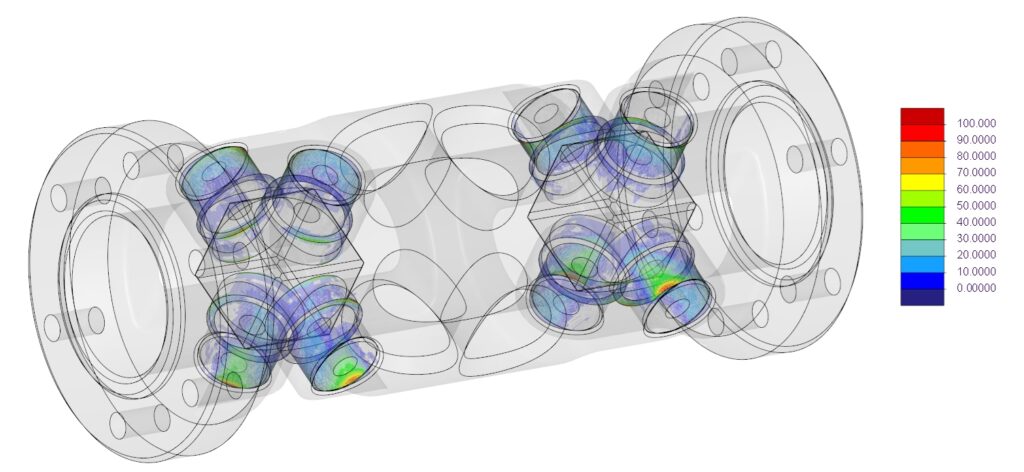

In the initial analysis stage, only geometric nonlinearity arising from contact interactions was taken into account. In a subsequent stage, material nonlinearity was introduced to capture the plastic response of the component, including yielding and residual deformations. This approach enabled the assessment of potential clearance formation and permanent displacements within the joint assembly.

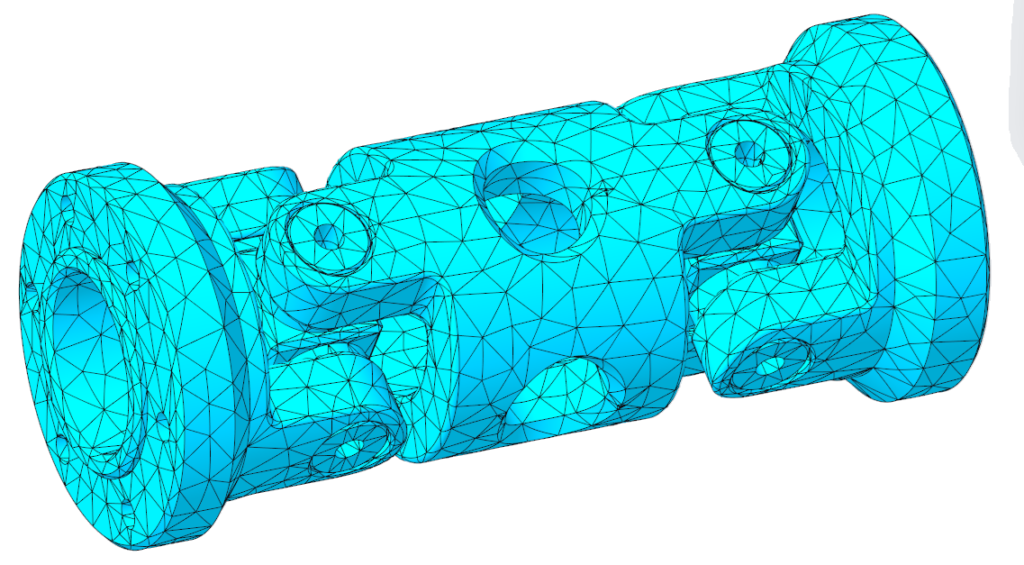

The solution of the nonlinear system required careful control of the discretization strategy. A p-element formulation based on variable-order polynomial elements was adopted. Strict mesh quality criteria were enforced with respect to both element size and geometric characteristics; in particular, excessively acute face angles and highly distorted element shapes were avoided in order to enhance numerical stability and convergence.

The solution of the nonlinear system required careful control of the discretization strategy. A p-element formulation based on variable-order polynomial elements was adopted. Strict mesh quality criteria were enforced with respect to both element size and geometric characteristics; in particular, excessively acute face angles and highly distorted element shapes were avoided in order to enhance numerical stability and convergence.

The mesh was further locally refined in the contact regions to improve the accuracy of contact pressure distribution and surface interaction modeling. Convergence was achieved within acceptable computational times due to the multi-core capabilities of the msengine. Post-processing of the results was conducted using the tools integrated within Creo Simulate Advanced.

The analysis of this model posed significant numerical challenges due to the simultaneous presence of multiple sources of nonlinearity, including complex contact interactions and material plasticity. The large number of contact interfaces, combined with geometric constraints that activate and deactivate during the load progression, resulted in a highly path-dependent response. Furthermore, the introduction of material nonlinearity led to stiffness degradation and localized plastic zones, which increased the sensitivity of the solution to load stepping, contact formulation, and mesh quality. These aspects required careful tuning of solver parameters and discretization strategies to ensure stable convergence and physically meaningful results.