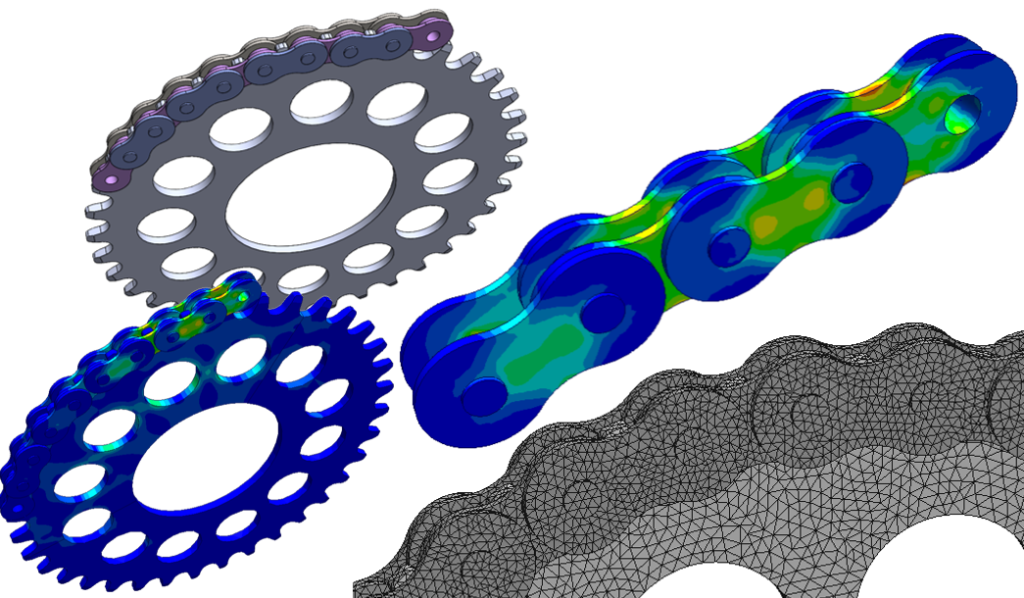

Predicting the stress concentration and premature tooth failure through advanced structural simulation.

A structural FEM simulation was carried out to assess the influence of chain elongation and sprocket stiffness on the stress distribution across the sprocket teeth. The analysis focused on identifying how wear-related deformations affect load sharing among teeth during operation. By simulating various degrees of chain elongation and material stiffness, it was possible to determine the threshold beyond which a single tooth begins to experience a significant increase in stress. This condition marks the onset of localised overload, potentially leading to rapid failure. The simulation thus enabled a precise definition of the maximum permissible wear before critical stress concentrations arise, supporting predictive maintenance and design optimisation.

To facilitate this analysis without breaching client confidentiality agreements, a bespoke case study was developed to emulate the intricate conditions encountered in actual applications. This approach enabled the exploration of a complex simulation scenario, particularly focusing on the numerous nonlinear contacts between the chain links and sprocket teeth. By replicating the real-world challenges of load transmission and wear progression, the study effectively mirrors the sophisticated calculations typically performed for our clients, thereby validating our simulation methodologies in a controlled yet representative environment.