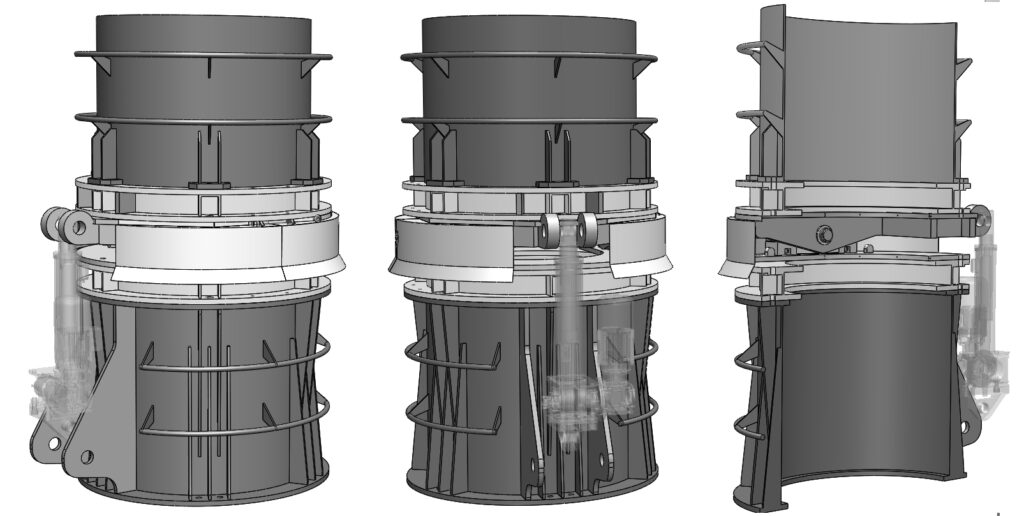

Mechanical design of an Industrial automation gripper

Altamax offers a specialized service for the design of custom equipment for integration with industrial robots. We primarily work with Creo Parametric, with the option to activate temporary licenses for other software such as Solidworks or Inventor, depending on the specific project requirements.

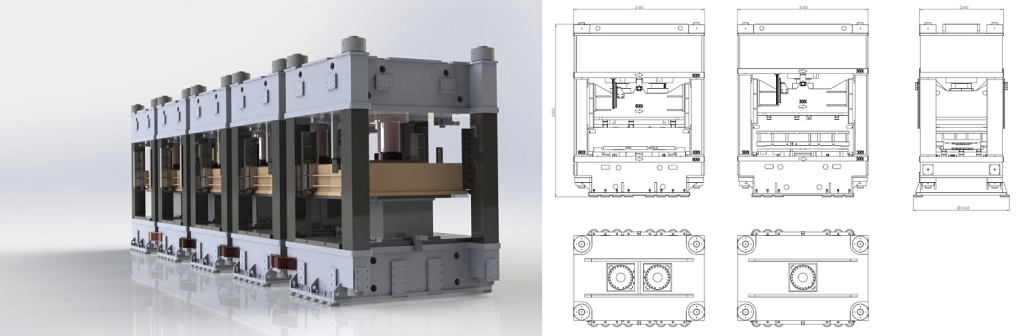

Thanks to our extensive experience in the mechanical and automation sectors, we develop tailor-made solutions that meet our clients’ specific needs, optimizing the performance of industrial robots. Our design process begins with a detailed analysis of the client’s needs, followed by the creation of accurate 3D models.

We use Finite Element Method (FEM) analysis for the structural sizing of the equipment, allowing us to simulate and test their behavior in a virtual environment before production. This approach ensures greater precision and helps reduce both the time and cost of implementation.

We design solutions for various industrial applications, including assembly, material handling, welding, and assembly. Each piece of equipment is designed to offer reliability, precision, and easy integration with existing robotic systems, improving the efficiency and flexibility of our clients’ operations.

Additionally, we provide comprehensive documentation at the end of each project, including native files, construction drawings, structural calculations, and calculation reports. Our team of engineers, with over 20 years of experience, ensures high-quality technical leadership and a stable point of contact for each client, guaranteeing a dedicated and consistent point of contact over time.